As we move into 2024, forward-looking manufacturers are setting their sights on the horizon and anticipating the economic upswing predicted for 2025. In this context, investing in automation appears to be a strategic decision that can set companies up for success when market conditions improve.

Automation: competitive advantage in manufacturing

.png?width=219&height=219&name=EN%20(1).png) Deloitte’s Outlook for the Manufacturing Industry to 2024 (1) further supports this view and highlights the critical need for manufacturers to embrace digital transformation and smart factory solutions to remain competitive. The report reveals that an overwhelming 86% of manufacturing executives surveyed believe smart factory solutions will be key drivers of competitiveness in the next five years (1).

Deloitte’s Outlook for the Manufacturing Industry to 2024 (1) further supports this view and highlights the critical need for manufacturers to embrace digital transformation and smart factory solutions to remain competitive. The report reveals that an overwhelming 86% of manufacturing executives surveyed believe smart factory solutions will be key drivers of competitiveness in the next five years (1).

Economist Alan Beaulieu, president of ITR Economics, strongly advocates this proactive approach. He emphasizes the importance of preparing for future growth by investing in automation and robotics now, and warns that “companies that do not invest in automation now will find themselves caught up when economic conditions improve in 2025” (2). This expert view reinforces the urgency of adopting automated solutions such as palletizing systems in the current economic climate.

Labor shortages are expected to deepen

.png?width=219&height=219&name=EN%20(2).png) Studies show that, short of anticipating an economic recovery, the labor shortages currently facing manufacturers are unlikely to ease; in fact, it is expected to get worse. According to Deloitte (3), even if every skilled worker in America were employed, there would still be 35% more unfilled jobs in the sustainable manufacturing sector than there are skilled workers to fill them. It predicts a shortage of more than two million American manufacturing workers by 2030.

Studies show that, short of anticipating an economic recovery, the labor shortages currently facing manufacturers are unlikely to ease; in fact, it is expected to get worse. According to Deloitte (3), even if every skilled worker in America were employed, there would still be 35% more unfilled jobs in the sustainable manufacturing sector than there are skilled workers to fill them. It predicts a shortage of more than two million American manufacturing workers by 2030.

Labor shortages are expected to deepen. Currently, approximately 40 million Baby Boomers remain in the workforce, making up 25% of the total workforce, with many in traditional manufacturing roles. As these boomers retire, younger workers increasingly choose jobs with better working conditions and pay and avoid manufacturing positions.

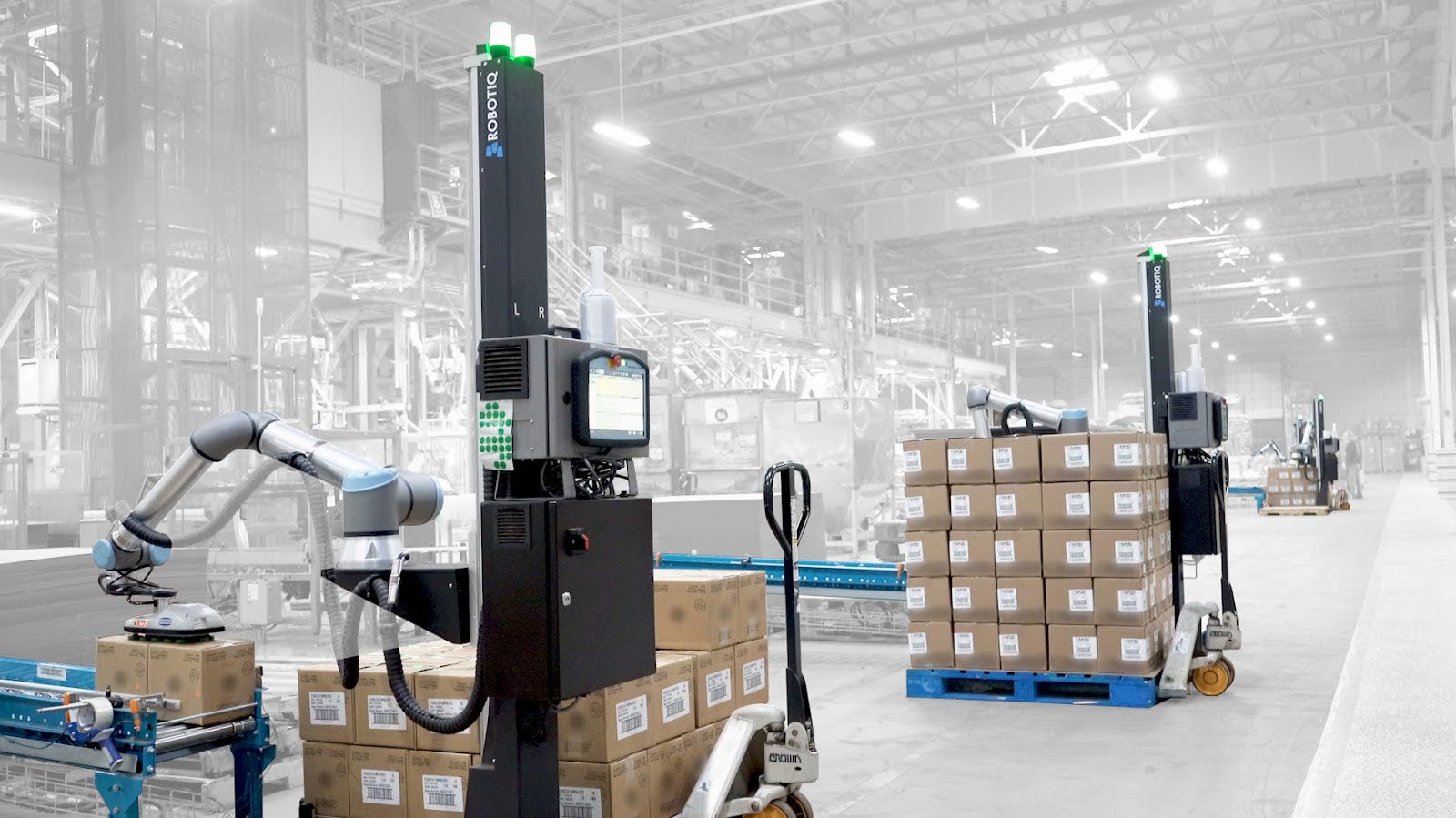

Cobots bring automation within reach

Recent innovations in automation have made this transition more affordable than ever before. Collaborative robot (cobot) palletizersIn particular, they have seen significant progress, becoming more efficient, more flexible and easier to integrate than their predecessors. These developments have democratized automation so that it is no longer the exclusive domain of large manufacturers. SMEs can now use these technologies to compete effectively in the global market.

They are a prime example of this new wave of accessible automation Robotiq Lean Cobot palletizers, solutions designed with ease of use and flexibility in mind. These systems embody the principles of lean manufacturing and offer a cost-effective (ROI less than a year), space-efficient and rapidly deployable solution for businesses of all sizes. Robotiq’s cobot palletizers demonstrate how modern automation can be tailored to the specific needs of each manufacturer, regardless of the scale of their operations.

By adopting these innovative solutions, manufacturers can not only prepare for the economic boom, but also cultivate a culture of continuous improvement and adaptability. Looking to 2025 and beyond, those who invest in smart and flexible automation solutions like cobot palletizers will be well-positioned to thrive in the evolving manufacturing landscape and turn today’s challenges into tomorrow’s competitive advantages.

Reference

(1) Deloitte. “Manufacturing Industry Outlook to 2024.” https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-outlook.html

(2) Control technology. “Manufacturing, Global Economy 2024-2025: Short-Term Pain, Then Growth.” https://www.controleng.com/articles/manufacturing-global-economy-2024-2025-short-term-pain-then-growth/

(3) Creating pathways for tomorrow’s workforce today

https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-diversity.html/#the-future